New device could lead to bumper microalgae harvests

- Algae industry could save up to 30% of costs with dewatering device

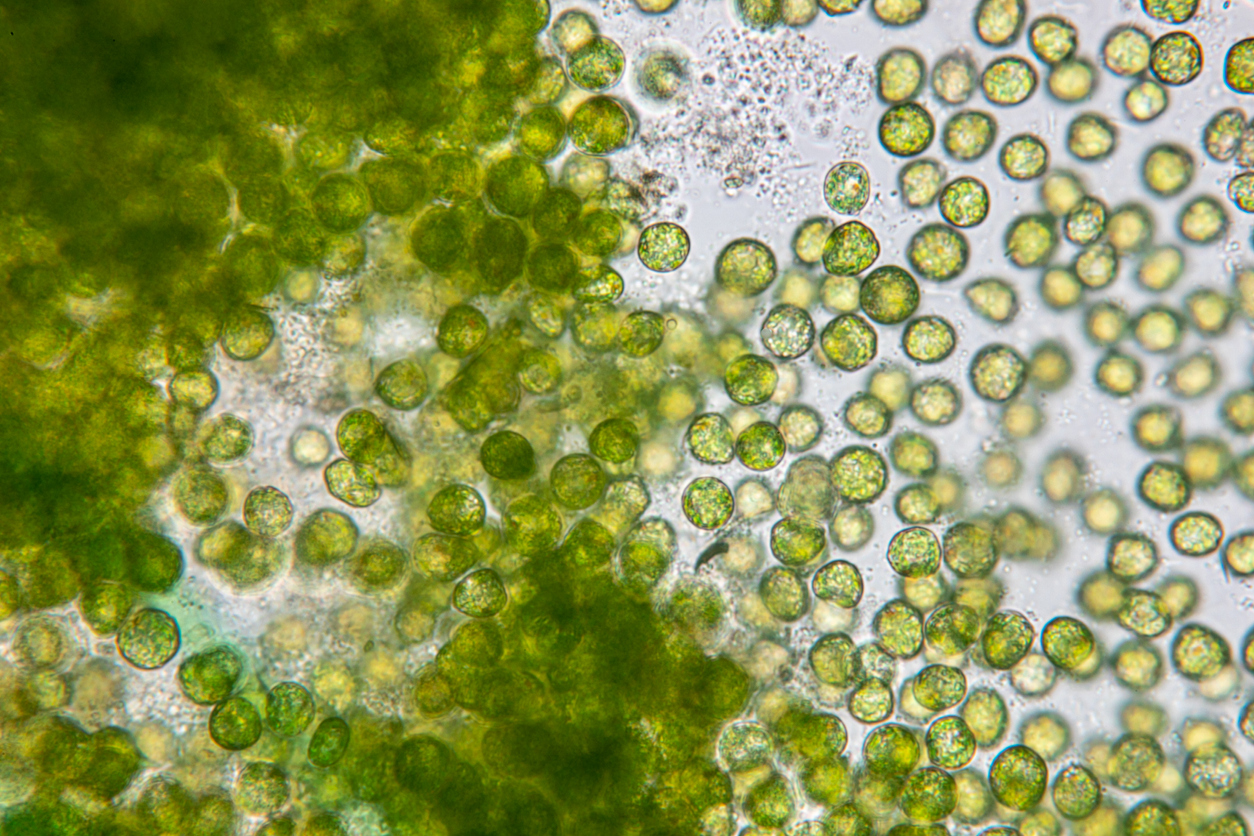

- Microalgae like chlorella are used as supplements, fertiliser, biofuels and more

Engineers at Heriot-Watt University are solving one of the biggest challenges facing microalgae producers: how to squeeze water out of the aquatic crop.

Algae production is a global industry, with crops used for supplements, food, fertiliser, biofuels and more.

Microalgae are microscopic plants, a much smaller version of algae like seaweed.

Dewatering is a problem in the production stage, as microalgae grow in very dilute solutions. Concentrating the microalgae and getting rid of the liquid is difficult and expensive.

Dr Helen Bridle, a microfluidics expert at Heriot-Watt University, has designed a device that could solve the problem.

Dr Bridle said: “Dewatering can account for thirty per cent of production costs because so much energy is required to remove the excess liquid.

“It’s especially difficult when dealing with smaller algae like chlorella, which is about five micrometres in size.”

Microalgae can grow in seawater or wastewater, so they don’t use up land or other resources. This means they could offer a sustainable way of making biofuels or other chemicals if production processes were more cost-effective.

Dr Bridle’s team designed a new microfluidics device that can deliver over 130 times concentration with over 95% recovery of algae.

“By exploiting a new mode of operation, employing recirculation and stacking our devices, we show the potential for microfluidics to be applied at the industrial level of microalgae harvesting.

“As samples get more concentrated they can clog up the devices, which is one of the problems with microfluidics. But we have reached volume fractions of over 65%, which is a huge step forward.

“Not only does this have direct cost benefits for producers, it means the process will use less energy and be more environmentally-friendly.”

The work is being done by Catherine Hill on an IBioIC funded PhD project and the team is working with Falkirk-based uFraction8 to commercialise the device.